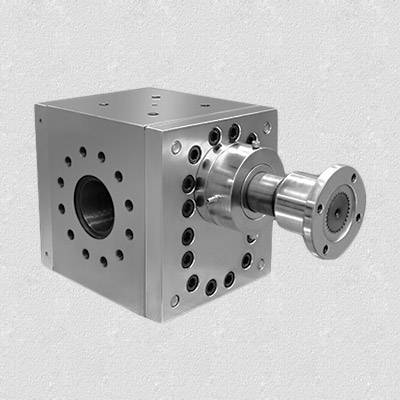

Dual Bolt Hydraulic Screen Changer (polymer filtration)

dual pillar continuous hydraulic screen changer for extruder adopts double columns and double nets for each column.The dual bolt hydraulic screen changer allows for the changing of polymer filtration screens without stopping production by alternating bewtween to bolt positions.

All gas in the polymer melt can be discharged through an advanced gas exhaust system design. This provides continuity and stability of the production process.

China dual bolt hydraulic extruder screen changers are used in compounding, masterbatch, recycling, sheet extrusion, profile extrusion, pipe production, pipe coating, and biaxial orientation.

-

Double piston pillar double screen cavities hydraulic screen changer

pillar piston

pillar piston hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

china plastic extruder screen changer for PET plastic extrusion and compounding is based on the proven double-piston design that operates without any additional seals. Their sturdy construction available in all sizes and designs guarantees a reliable and leak-free filtration of polymer melt for many years.

-

Double piston four screen cavities continuous screen changer

pillar piston

pillar piston hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

As double column (exhaust) hydraulic screen changer four screen cavities screen changer, four working station can work simultaneously which can provide uninterrupted operation. It’s suitable for chemical fiber, blown film, flat film, cast film, pipe, plate, wire, fiber, granulating, recycling, pelletizing, etc.

-

Double piston four screen cavities backflush hydraulic screen changer

pillar piston

pillar piston hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

This series double pillar screen changer supply is suitable for high productivity, high efficiency, high quantity and continuous production of large extrusion plant.Especially used for plastic recycling line and addition of large proportion of recycled plastic. With backflush function, it can backflushing filter during production, the filter screen can be used repeatedly than 200 times.

-

plastic extrusion screen changer

slide plate

slide plate hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

Double piston screen changer and continuous screen changer for extrusion and compounding from BATTE with their robust and leak-free operation meet highest quality standards with respect to melt filtration. Due to their constantly improved functionality Continuous screen changers and double pistion screenchangers for filtration systems from BATTE increase product quality significantly.

Other hot melt filter screen changer

-

Automatic mesh belt continuous screen changer

-

Single plate hydraulic screen changer with four working station

-

Double plate continuous hydraulic screen changer

-

Single plate double screen cavities screen changer

-

screen melt filter for extrusion plastic machine

-

plastic extrusion screen changer

-

Manual control screen changer

-

boosting pressure extrusion melt pump

hot melt filter screen changer vedio

-

batte screen changer

-

batte melt pump

-

Single screw gravimetric dosing feeder

-

Multi-component loss in weight feeder

-

ZB-F series melt pump for reaction kettle

-

PLC Control System for extruder