Melt Pump

- Polymer extrusion melt gear pump

- melt pump for plastic extrusion

- Polymer Reaction Kettle pump

- gear pump rubber extruder

- melt pumps for extrusion

- Melt Gear Pumps for BOPP Films

- ZB-G bearing external melt pump

- melt pump for pvc extrusion

- ZB double shaft drive melt pump

- Explanation of terms for melt pump d

- ZB-X Series chemical gear melt pump

- PID Control System for extrusion

- PLC Control System for extruder

- ZB-U series melt extrusion spinning

- ZB-E series transfer melt pump for e

- ZB-H series high temperature and hig

- ZB-R series gear melt pump for rubbe

- ZB-K series chemical stainless steel

- ZB-D series pipeline melt pump for p

- ZB-F series melt pump for reaction k

- ZB-B series dosing standard thermopl

- ZB-C series plastic granule machine

Screen Changer

- polymer melt filtration screen changer

- recycled plastic screen changer

- slide plate screen changer

- pillar screen changer

- dual bolt screen changer

- continuous screen changer

- screen changer polymer filter

- Plastic extruder filter extrusion sc

- Biodegradable plastic PBAT/PLA hydra

- Single plate hydraulic screen change

- plastic extrusion screen changer

- single plate hydraulic quick screen

- Manual control screen changer

- Double plate continuous hydraulic sc

- Automatic mesh belt continuous scree

- Double piston four screen cavities c

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Dual Bolt double screen cavities hyd

Feeding System

- force feeder extruder

- loss in weight feeder for masterbatc

- continuous feeding system

- Liquid loss in weight feeder

- china volumetric screw doser feeder

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

melt blown progress

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: sale@meltpump.com

- whatsapp: +86 158 38331071

- Tel: +86-371-67991755 / 67992755

- FAX:+86-371-67993277

- Address:No.11 Changchun Road, High-tech Zone, Zhengzhou, China.

News

- Melt gear pump core technology princ

- Underwater granulation screen change

- Chemical melt gear pump

- Mesh belt automatic non-stop screen

- Theoretical and Actual Flow Rate of

- High-Transparency PET Sheet Extruder

- Rubber extrusion melt pump

- Which plastic extrusion production l

- Precision extruder melt pumps for th

- Melt gear metering pump role and par

About Batte Machinery

Batte people in the exhibition

Batte Melt Pump Zhengzhou Co., Ltd. is one of the manufacturers of melt pumps, gear pumps, metering pump and loss-in-weight feeders, volumetric feeders,screen changer in China. Batte has many experienced and outstanding plastic machinery talents, so it can continuously develop the new products by self-innovation or by introduction and absorbing new technology, meanwhile Batte also improves constantly the design of products and production technology service.

Part of Batte's factory

Batte's policy is to be based on continuous researches and exploitations. That makes us manufacture high-tech and high efficient products which have excellent reliability. All raw materials and spare parts of products are selected carefully and assembled with skilled experience. Pre-delivery debugging of melt pumps is the best quality assurance before they are leaving the factory.

Batte is aimed at improving customers' usage value by our ongoing efforts and supporting better services, thus receiving recognition and more orders from customers.

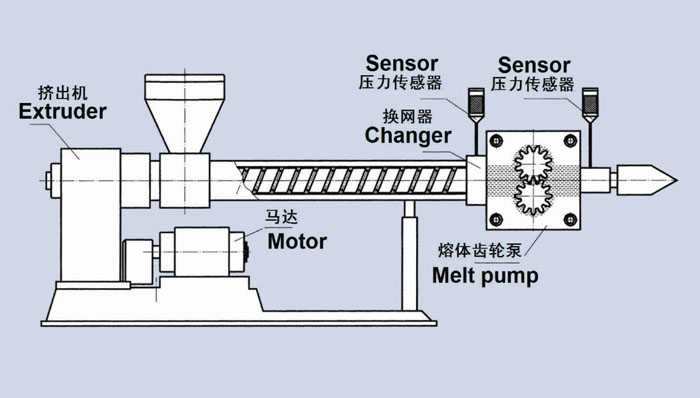

Melt pump system running in the extruder production line

Our pumps are widely used in plastic, resin, plate, sheet and rubber extrusion. For example, plastic extrusion machinery for PA, PP, PS, PE, PET, PC, ABS and so on is all using melt pumps to eliminate extruders' surge and screws' beat.

Our feeders are suitable for different kinds of powders. Networking loss-in-weight feeding equipment supports the unified database, in order to realize the process which is based on database system. Configurable options can meet factories' demands in health and are explosion proof, waterproof and corrosion resistant.

Our screen changer can not only filter the impurities, but also can significantly improve the plasticizing and homogenization effect of the raw material. In this way, it can make the product structure more homogeneous and product surface more smooth, thus improve the quality of extruded products. In a word, Batte screen changer can reduce the unit cost and increase hourly output.

Our product are exported to Taiwan, Japan, USA, Turkey, Mexico, Brazil, Russia, India, Malaysia, Vietnam, Iran, and other countries and regions and received high praised by our customer.

Batte Team: Batte has a strong engineer team with international professional level, and commits to offer customers with high quality products and to provide satisfied service, create the market value.

Batte Mission: committed to plastic extrusion processing, the development of energy saving, the environmentally friendly products, the establishment of industry’s leader, and the creation of well-known brand at home and abroad.

Our advantages:

1. we have CE,ISO,SGS and BV certificate;

2. we have 11-year experience;

3. we are a leading brand in China;

4. we have over 100 workers to ensure quick delivery;

5. we have 10 engineers to design special concrete plants for our customers;

6. we have after sales service like: installation, debugging, operator trainning and spare parts supply.