recycled plastic screen changer

Recycling of plastic raw materials, especially materials that are used in food and beverage packaging such as PET, which require large amounts of consumption Not only will it benefit the ecological environment, but more importantly, it will have a huge economic effect. As a result, many new technologies and processes on how to clean and recycle warm plastics have emerged, such as mechanical filtration processes (to filter solid particles from the melt). In order to meet the requirements of the process and minimize the production cost of recycling, BATTE specially designed the ZB-DP series of china plastic screen filter changer.

-

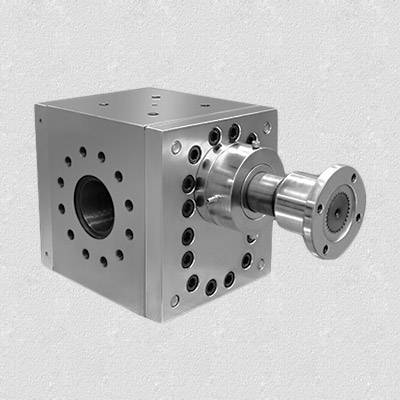

Double piston pillar double screen cavities hydraulic screen changer

pillar piston

pillar piston hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

double piston plastic screen changer for PET plastic extrusion and compounding is based on the proven double-piston design that operates without any additional seals. Their sturdy construction available in all sizes and designs guarantees a reliable and leak-free filtration of polymer melt for many years.

-

china Double piston four screen cavities continuous screen changer

pillar piston

pillar piston hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

As double column (exhaust) china plastic extruder screen changer four screen cavities, four working station can work simultaneously which can provide uninterrupted operation. It’s suitable for chemical fiber, blown film, flat film, cast film, pipe, plate, wire, fiber, granulating, recycling, pelletizing, etc.

-

Double piston four screen cavities backflush hydraulic screen changer

pillar piston

pillar piston hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

pet chemical fiber filter mesh changer supply is suitable for high productivity, high efficiency, high quantity and continuous production of large extrusion plant.Especially used for plastic recycling line and addition of large proportion of recycled plastic. With backflush function, it can backflushing filter during production, the filter screen can be used repeatedly than 200 times.

-

Double plate continuous hydraulic screen changer with two working station

slide plate

slide plate hydraulic

hydraulic non-stop screen changer

non-stop screen changer continuous

continuous

plastic extruder screen changer with double working station realizes non stop screen changing operation by two pillar with double filtering areas. Designed lead material exhaust structure, during changing screen with material flow no stop,then realize on-stop screen changer.

Other hot melt filter screen changer

-

Automatic mesh belt continuous screen changer

-

Single plate hydraulic screen changer with four working station

-

Double plate continuous hydraulic screen changer

-

Single plate double screen cavities screen changer

-

screen melt filter for extrusion plastic machine

-

plastic extrusion screen changer

-

Manual control screen changer

-

boosting pressure extrusion melt pump

hot melt filter screen changer vedio

-

batte screen changer

-

batte melt pump

-

Single screw gravimetric dosing feeder

-

Multi-component loss in weight feeder

-

ZB-F series melt pump for reaction kettle

-

PLC Control System for extruder