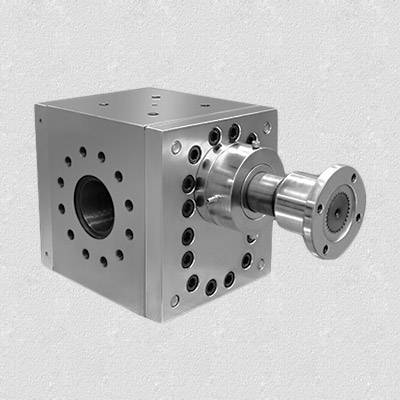

Melt Pump

- Polymer extrusion melt gear pump

- melt pump for plastic extrusion

- Polymer Reaction Kettle pump

- gear pump rubber extruder

- melt pumps for extrusion

- Melt Gear Pumps for BOPP Films

- ZB-G bearing external melt pump

- melt pump for pvc extrusion

- ZB double shaft drive melt pump

- Explanation of terms for melt pump d

- ZB-X Series chemical gear melt pump

- PID Control System for extrusion

- PLC Control System for extruder

- ZB-U series melt extrusion spinning

- ZB-E series transfer melt pump for e

- ZB-H series high temperature and hig

- ZB-R series gear melt pump for rubbe

- ZB-K series chemical stainless steel

- ZB-D series pipeline melt pump for p

- ZB-F series melt pump for reaction k

- ZB-B series dosing standard thermopl

- ZB-C series plastic granule machine

Screen Changer

- polymer melt filtration screen changer

- recycled plastic screen changer

- slide plate screen changer

- pillar screen changer

- dual bolt screen changer

- continuous screen changer

- screen changer polymer filter

- Plastic extruder filter extrusion sc

- Biodegradable plastic PBAT/PLA hydra

- Single plate hydraulic screen change

- plastic extrusion screen changer

- single plate hydraulic quick screen

- Manual control screen changer

- Double plate continuous hydraulic sc

- Automatic mesh belt continuous scree

- Double piston four screen cavities c

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Dual Bolt double screen cavities hyd

Feeding System

- force feeder extruder

- loss in weight feeder for masterbatc

- continuous feeding system

- Liquid loss in weight feeder

- china volumetric screw doser feeder

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

melt blown progress

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: sale@meltpump.com

- whatsapp: +86 158 38331071

- Tel: +86-371-67991755 / 67992755

- FAX:+86-371-67993277

- Address:No.11 Changchun Road, High-tech Zone, Zhengzhou, China.

News

- Single-Column Dual-Station Hydraulic

- Differences Between Reactor Melt Dis

- BATTE cordially invites you to visit

- single-plate hydraulic screen change

- BATTE Melt Pumps Replace MAAG Pumps

- Application of Melt Pumps in Sheet E

- Melt Pump for PP Filament Production

- Melt Gear Pump Selection 3D Matrix:

- Melt pumps and screen changers are u

- Accessories for melt pumps

Melt pump manufacturer tells the working principle of external meshing gear pump

Gear pumps are generally divided into external gear pumps and internal gear pumps according to their different structures. Their basic working principles are the same. Since external gear pumps are widely used, if there is no special description, most gear pumps refer to external gear pumps. Zhengzhou Bart's melt pump manufacturer will describe the working principle of external gear pump in detail.

- 1. The suction and discharge of the melt gear pump is caused by the rotation of a pair of meshing gears. The volume of the chamber exiting the meshing side increases and the pressure decreases, and the volume of the chamber entering the meshing side decreases, and the pressure increases. Big. china melt gear pumps rely on volume changes to produce suction and discharge work, which is a type of volumetric fixed displacement pump.

- 2. In order to seal the chamber and reduce leakage loss, the sealing performance should be good, that is, the meshing contact of the tooth surface should be good, the radial clearance between the outer circle of the tooth top and the inner wall of the pump body, the two ends of the gear and the front and rear end covers of the pump body The axial gap between them should be small. The smaller the gap, the smaller the internal leakage loss, the higher the volumetric efficiency, and the higher the suction performance and discharge pressure.

- 3. The suction and discharge of the melt gear pump are continuous, but the displacement is not uniform enough and brings about pressure pulsation. The unevenness and pulsation rate depend on the number of gear teeth, tooth profile and speed.

- 4. Hot melt gear pump does not need suction and discharge valves, and has no reciprocating parts. Therefore, its structure is relatively simple, the cost is low, and the management and maintenance are simple and convenient.

- 5. When the melt gear pump is working, the contact stress of the tooth surface is relatively large, and the wear of the tooth surface is relatively large, so it is only suitable for transporting liquids with good lubrication performance and less impurities.

Since Zhengzhou Bart specializes in the production of high-temperature extruder melt gear pumps, it has accumulated rich experience in the application technology of high-temperature high pressure melt gear pump, and provides a new generation of gear pumps with the advantages of high quality, high efficiency, and long life.

Previous:Why the reactor melt pump adopts herringbone gearNext:How Melt Blown Cloth Melt Pumps Could Get You on The Today Show